Are you an EPFL student and looking for a semester credited, Bachelors or Masters Project ? Look no further! We have something for you!

If you can’t find your dream project down here, but have an idea or would like to suggest your own project to do with us, we are open to suggestions! Feel free to contact us and we can talk about it.

Autumn 2026

COMPETITION PROJECT

Payload

PROJECT DESCRIPTION

Context: The EPFL Rocket Team is developing a new class of supersonic rockets, with planned launches reaching 9 km in 2026 and 30 km in subsequent missions. As rockets become faster and more powerful, understanding the effects of dynamic loads—such as vibrations and accelerations—becomes critical for ensuring structural integrity and reliable payload performance. In professional aerospace projects, organizations like NASA, ESA, and SpaceX conduct extensive testing and publish integration manuals to guide external partners in designing payloads that can withstand these environments. Following this model, our team is beginning to address the same challenges at the student level.

Project overview : This project focuses on the first in-flight measurement campaign of dynamic loads within our rockets. The payload subsystem will install a dedicated suite of sensors to capture vibrations, accelerations, temperature, and related effects during the next launch. The resulting dataset will serve two purposes: to enhance our internal understanding of rocket behavior and to provide practical information that other subsystems can use to incorporate dynamic load considerations into their designs. In addition, the project will produce a user manual for external laboratories and companies, laying the groundwork for safe and reliable payload integration in future flights.

WHAT THE STUDENT(s) WILL DO:

- Literature review on existing methods

- Selection of appropriate sensors

- Deformations

- Vibrations

- Temperature

- Study of sensor placement

- Study of data treatment methods

- First draft of a user manual for external payloads

SKILLS INVOLVED:

- Structural Dynamics

- Vibrational Mechanics

- Measurement Techniques

STUDENT GAIN:

- Opportunity to tackle industry-relevant problems

- Opportunity to bridge theory with practical engineering challenges

TASKS UNFOLDING:

- [3 weeks]: Literature Review

- [7 weeks]: Sensor Selection and Positioning

- [4 weeks]: User Manual First Draft and Report

Contacts: rafael.boisel@epfl.ch

Supervisor: TBD

Status: TAKEN

Reference links:

Flight Dynamic

PROJECT DESCRIPTION

Context: The EPFL Rocket Team is developing a new class of supersonic rockets, with planned launches reaching 9 km in 2026 and 30 km in subsequent missions. These launch vehicles are propelled by a bi-liquid engine fed by two cylindrical aluminium tanks located along the rocket length that store the propellant and oxidiser. The in-flight accelerations experienced by the rocket can cause the fluid located inside the tanks to ‘move around’ (see image). This phenomenon is called sloshing and can lead to flight instabilities due to the movement of the center of mass of the rocket and to the generated internal forces.

Figure: CFD snapshot of propellant sloshing in a truck cylindrical tank.

Project overview: This project focuses on verifying previous reduced-order mechanical models by using CFD. The student will have to account for both the liquid and the gas phase and perform transient simulations while modelling the in-flight accelerations. The results of these simulations should help the team incorporate the best countermeasures in the design of the tanks, which the student will also be required to model and evaluate within the simulation framework.

WHAT THE STUDENT(s) WILL DO:

- Literature review on existing methods and empirical approaches

- Design of countermeasures (baffles…)

- CFD simulations of tanks with and without added counter-measures

- Post-processing of data to verify the results

- Result comparison with empirical approaches and validation

- Documentation of process and results

SKILLS INVOLVED:

- CAD Design

- CFD Simulations

- Fluid Dynamics

- Fluid Structure Interaction

STUDENT GAIN:

- Opportunity to tackle industry-relevant problems

- Opportunity to work on complex simulations

TASKS UNFOLDING:

- [2 weeks]: Literature Review

- [8 weeks]: Design and Simulations

- [2 weeks]: Comparison and Validation

- [2 weeks]: Documentation

Contacts: rafael.boisel@epfl.ch

Supervisor: TBD

Status: AVAILABLE

PROJECT DESCRIPTION

Context: The EPFL Rocket Team is developing a new class of supersonic rockets, with planned launches reaching 9 km in 2026 and 30 km in subsequent missions. These launch vehicles are propelled by a biliquid engine fed by two cylindrical aluminum tanks located along the rocket length that store the propellant and oxidizer. The in-flight accelerations experienced by the rocket can cause the fluid located inside the tanks to ‘move around’. Sometimes, this means vortices can appear at rocket tank outlets, just like in bathtubs or sinks when they are being emptied. These vortices can lead to instabilities in the mass outflow rate, which can have undesired effects on the propulsion system.

Project overview: This project focuses on verifying previous empirical based approaches by using CFD. The student will have to account for both the liquid and the gas phase and perform transient simulations while modeling the in-flight accelerations. The results of these simulations should help the team incorporate the best counter-measures in the design of the tanks.

WHAT THE STUDENT(s) WILL DO:

- Literature review on existing methods and empirical approaches

- Design of countermeasures (baffles…)

- CFD simulations of tanks with and without added counter-measures

- Post processing of data to verify the results

- Result comparison with empirical approaches and validation

- Documentation of process and results

SKILLS INVOLVED:

- CFD Simulations

- Fluid Dynamics

- Fluid Structure Interaction

STUDENT GAIN:

- Opportunity to tackle industry-relevant problems

- Opportunity to work on complex simulations

TASKS UNFOLDING:

- [2 weeks]: Literature Review

- [7 weeks]: Design and Simulations

- [3 weeks]: Comparison and Validation

- [2 weeks]: Documentation

Contacts: rafael.boisel@epfl.ch

Supervisor: TBD

Status: AVAILABLE

PROJECT DESCRIPTION

Context: The EPFL Rocket Team is developing a new class of supersonic rockets, with planned launches reaching 9 km in 2026 and 30 km in subsequent missions. These launch vehicles will be propelled by a regeneratively-cooled bi-liquid engine (Lox-Ethanol engine), aiming to achieve a thrust of 7.5 kN to 15 kN. To keep the engine from melting, the ethanol is first passed through some channels around the combustion chamber before entering the manifold which allows the liquids to mix into the combustion chamber.

Figure: Cooling channels around the C1 engine

Project overview: This project aims at guiding the design phase of future engine cooling channels and manifold geometry by first comparing CFD simulation data to a previously manufactured and tested design (the B1 engine) before working on the next engine: C1. CFD simulations will be performed to analyse and verify film cooling performance and manifold efficiency, before entering a CAD design phase to propose improved data-backed designs.

WHAT THE STUDENT(s) WILL DO:

- Literature review on existing methods and previous designs

- CFD simulations on B1 to verify simulation model compared to test measurements

- CFD simulations on C1 to verify requirements

- Design of improved channels and manifold

- Post-processing of data to verify results

- Documentation of process and results

SKILLS INVOLVED:

- CFD Simulations

- Fluid Mechanics

- Heat Transfer

- Fluid Structure Interaction

STUDENT GAIN:

- Opportunity to tackle industry-relevant problems

- Opportunity to work on complex simulations

TASKS UNFOLDING:

- [2 weeks]: Literature Review

- [3 weeks]: B1 Simulations (simulation model setup)

- [3 weeks]: C1 Simulations (requirement verification)

- [4 weeks]: Design and Simulation of New Designs

- [2 weeks]: Documentation and Report

Contacts: rafael.boisel@epfl.ch

Supervisor: TBD

Status: AVAILABLE

Structure

PROJECT DESCRIPTION

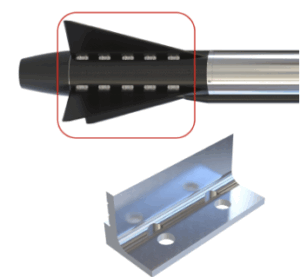

Context: Clamps are essential components of the rocket structure, ensuring the attachment and retention of the fins. Their design must meet various mechanical constraints: they must withstand the axial forces generated during launch, resist the torsional moments induced by in-flight loads, and have sufficiently high natural frequencies to avoid any resonance with the rocket’s vibration excitations.

Currently used versions have significant limitations: they are too heavy, which negatively impacts overall performance, and their mechanical behavior is not considered optimal. The project therefore aims to develop a lighter and more rigid design, while remaining compatible with available machining processes.

Project overview: The goal of this project is to design and validate a new generation of fixation system for the fins using numerical tools and professional aerospace standards of test (e.g., ESA, NASA).

The work will be divided into three main stages. First, a literature and documentation review will be carried out to analyse the limitations of previous designs and to define the mechanical requirements. Then, a design and simulation phase will be conducted, where several geometries will be developed using CAD and FEM. Numerical analyses will include modal analysis to verify axial and torsional resistance, as well as the position of natural frequencies. Finally, an experimental validation phase will take place, including the machining of prototypes and mechanical testing to compare experimental results with the numerical predictions and validate all requirements. If the manufacturing process takes too much time for any reason, a complete report on the manufacturing method, as well as the preparation and writing of a testing specification, will be required.

WHAT THE STUDENT(s) WILL DO:

- CAD design of different clamp geometries, taking into account mass reduction, stiffness, and manufacturability.

- FEM simulations (structural and modal analysis) to evaluate axial and torsional resistance, as well as natural frequencies.

- Machining of selected prototypes and preparation of experimental setups.

- Experimental testing of the prototypes (static and modal tests) and comparison with simulation results.

SKILLS INVOLVED:

- Modal analysis

- Practical testing

- FE Simulations

- ANSYS (Mechanical)

STUDENT GAIN:

- Gaining experience in simulation validation

- Gaining experience in structural dynamics

- Gaining experience in practical testing

TASKS UNFOLDING:

- [2 weeks] Review of documentation.

- [3-4 weeks] CAD design of new clamp concepts and Fem Analysis.

- [4 weeks] Machining of prototypes.

- [3-4 weeks] Experimental tests and comparison with simulations.

- [1 week] Final report and recommendations.

Contacts: gabriel.mollet@epfl.ch

Supervisor: TBD

Status: TAKEN

PROJECT DESCRIPTION

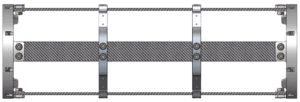

Context: In order to dimension the structural parts of its rockets, the EPFL Rocket Team mainly uses structural simulations based on the Finite Element Method (FEM). Simulating an entire structural segment (like the one in the image below) is a difficult task, in part because the contacts between all of the different parts introduce a lot of nonlinearities. Moreover, using destructive testing to verify/validate simulations can be very expensive.

Figure: Side view of a segment of the rocket internal structure, its 4 carbon rods (3 visible), and its aluminum anti buckling rings. The entire rocket is composed of multiple structural segments like this one.

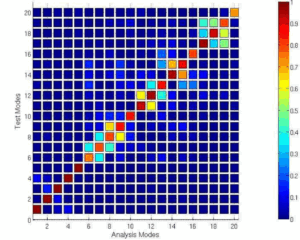

A common method used in aerospace engineering to verify/validate large coupled FE models is to compare simulated and experimental modal analysis. By experimentally extracting the modal frequencies and mode shapes and correcting the FE models until the simulation results match with the experiment, it is possible to verify and correct large coupled FE models in a non-destructive manner.

Project overview : This project has three goals: to establish a procedure/methodology to conduct experimental modal analysis, to establish a methodology to update FE models to match with experimental results, and to apply both methodologies on a rocket structural segment as a case study. The experimental modal analysis can be done using accelerometers and impulse excitation (hammer). The finite element model to validate will be created in ANSYS, which will also be used for the simulated modal analysis.

Figure: Modal Assurance Criterion (MAC) matrix typically used to compare experimental and simulated modes[1].

WHAT THE STUDENT(s) WILL DO:

- Define how to perform experimental modal analysis according to the association’s budget and resources

- Perform experimental modal analysis on a provided rocket structural assembly

- Define how to correct FE models according to experimental modal results

- Correct a provided FE model until predefined accuracy criteria are met

SKILLS INVOLVED:

- Structural dynamics

- Modal analysis

- Practical testing

- FE Simulations

- ANSYS (Mechanical)

STUDENT GAIN:

- Gaining experience in practical testing

- Gaining experience in simulation validation

- Gaining experience in structural dynamics

- Opportunity to work on a complex and very advanced structural engineering topic

TASKS UNFOLDING:

- [2 weeks]: Literature review

- [5 weeks]: Setting up experiment

- [2 weeks]: Experimental analysis

- [4 weeks]: FE Model correction

- [1 week]: Documentation

Contacts: gabriel.mollet@epfl.ch

Supervisor: TBD

Status: TAKEN

PROJECT DESCRIPTION

Context: The EPFL Rocket Team is developing rockets that reach progressively higher altitudes each year: 9 km in 2026, then 30 km, and eventually up to 100 km.

As part of this progression, we are designing a parachute separation system that uses pyrocutter technology combined with precision-machined aluminum components.

As the rocket becomes more powerful and faster, it faces increasingly extreme conditions: low pressure and reduced oxygen at high altitude, very low temperatures, intense vibrations and accelerations,humidity accumulation on the launch pad, etc… These factors can compromise the reliability of the mechanism.

Our goal is to design and test new prototypes capable of operating reliably in such environments, drawing inspiration from the methods and standards applied in professional aerospace projects.

Project overview : This project focuses on the improvement and testing of a separation system used on the first 2025 vehicle, which reached 3 km, as well as on the next rocket planned to reach 9 km. The work will begin with a thorough review and analysis of all existing documentation related to these components, followed by the redesign of a more optimal mechanism — aiming for improvements in mass, cost, simplicity of assembly, and above all, reliability.

The project will also involve studying professional testing methodologies employed by agencies such as NASA and ESA, with the goal of planning and conducting as many relevant tests as possible in extreme environments. Finally, detailed tracking and documentation of all operations will be maintained to provide a clear basis for validating — or refuting — the integration of this subsystem into the rocket.

WHAT THE STUDENT(s) WILL DO:

- Review and analyze the existing documentation

- Redesign the mechanism in CAD software (SolidWork) and machine it.

- Prepare the test operations and documentation (Test Specification and Procedure)

- Design and machine the test fixtures of an extreme environment

- Conduct the tests

- Write the test reports

SKILLS INVOLVED:

- CAD designing

- Machining

STUDENT GAIN:

- Opportunity to learn professional testing and documentation methods

- Opportunity to learn machining techniques

- Opportunity to work on a multidisciplinary project

TASKS UNFOLDING:

- [2 weeks]: Literature Review.

- [2-3 weeks]: Redesign and Machining

- [3-4 weeks]: Prepare Testes and fixtures

- [2 weeks]: Testing

- [2-3 weeks]:

- Redesigning if necessary

- Re-testing

- Writing Test Report

Contacts: gabriel.mollet@epfl.ch

Supervisor: TBD

Status: TAKEN

Propulsion

PROJECT DESCRIPTION

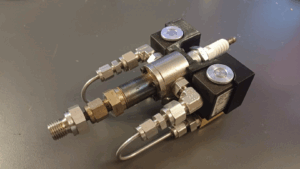

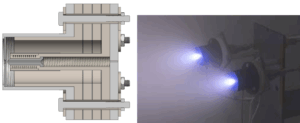

Context: The EPFL Rocket Team is currently developing a new rocket architecture aimed at launching successively at an altitude of 3 km during the EuRoC 25 student rocketry competition, at an altitude of 9 km in 2026 and at an altitude of 30 km in 2028. Each new launch vehicle will benefit from the lessons learned from the previous launchers to gradually increase the performance and the reliability of the architecture. These launch vehicles are propelled by a regeneratively-cooled biliquid engine, aiming a thrust from 7.5 kN to 15 kN. To fire these engines, we are developing a torch igniter fed by the same propellant as the actual engine (i.e Liquid Oxygen and Ethanol). This torch igniter should provide an easy and reliable way of lighting up a rocket engine during its test campaign and the actual launch. The existing design is currently working with N2O and Ethanol as propellant and has to be adapted for Liquid Oxygen and Ethanol.

Figure: Torch igniter current design.

Project overview : This semester project aims to extensively test the existing design of the torch igniter to determine the parameters allowing it to fire reliably, and if necessary, to propose a new design. The test campaign will take place in the ERT Testing Facility in Savigny.

WHAT THE STUDENT(s) WILL DO:

- Review the design and the previous test data

- Prepare a design of experiment for the new test campaign

- Test the existing torch igniter at the Testing Facility of the EPFL Rocket Team

- Analyse the test data to understand its behaviour

- Improve the existing design

SKILLS INVOLVED:

- Testing

- Fluid mechanics

- Machining mechanical part

- Problem solving

STUDENT GAIN:

- Experience in testing a rocket propulsion device

- Design of a rocket propulsion device

- Use of a remotely controlled testing facility

- Working with high-pressure fluid system

TASKS UNFOLDING:

- [2 weeks]: Design and literature review

- [2 weeks]: Test preparation

- [5-6 weeks]: Testing

- [2-3 weeks]: Design and manufacturing

- [1 week]: Documentation

Contacts: sven.profichet@epfl.ch

Supervisor: Markus Jäger

Status: TAKEN

PROJECT DESCRIPTION

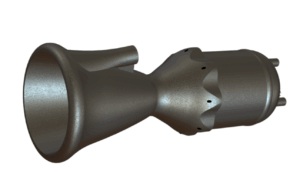

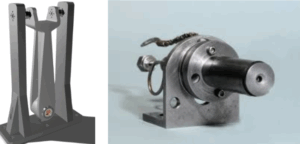

Context: The EPFL Rocket Team is currently developing a new rocket architecture aimed at launching successively at an altitude of 3 km during the EuRoC 25 student rocketry competition, at an altitude of 9 km in 2026 and at an altitude of 30 km in 2028. Each new launch vehicle will benefit from the lessons learned from the previous launchers to gradually increase the performance and the reliability of the architecture. These launch vehicles are propelled by a regeneratively-cooled biliquid engine, aiming a thrust from 7.5 kN to 15 kN. The launch vehicle aiming 3 and 9 km of altitude are propelled by an engine of B class designed for a maximum thrust of 7.5 kN. To reach an apogee of 30 km, a new engine class has to be developed, C class, aiming for a thrust of 15 kN. A preliminary design was made in spring 2025 as a Bachelor Project and this Semester Project is the direct continuation of it.

This new engine, Demo-C1, must use Liquid Oxygen and Ethanol as propellants, include cooling (regenerative and/or film cooling) and be manufactured with an additive manufacturing technique.

Figure: Demo C1 current design.

Project overview : This semester’s project aims to continue the design of Demo-C1 to match the requirements of the Firehorn 3 launch vehicle and make it realisable in additive manufacturing.

WHAT THE STUDENT(s) WILL DO:

- Review the actual design

- Improve the actual design, notably the regenerative cooling system

- Verified the design with thermomechanical simulations

- Propose a critical design of Demo-C1

- Ensure that the design is adapted to additive manufacturing

SKILLS INVOLVED:

- CAD design

- Fluid mechanics simulation

- Rocket propulsion

STUDENT GAIN:

- Experience in rocket propulsion

- Experience in CAD design of a rocket combustion chamber

- Experience in thermomechanical simulations

- Experience in additive manufacturing

TASKS UNFOLDING:

- [1 week]: Design and literature review

- [5-6 weeks]: CAD design

- [2-3 weeks]: Simulations

- [2 weeks]: Manufacturing preparation

- [2 week]: Documentation

Contacts: sven.profichet@epfl.ch

Supervisor: Markus Jäger

Status: TAKEN

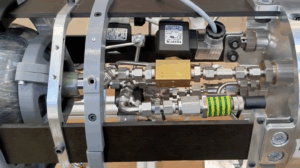

PROJECT DESCRIPTION

Context: The EPFL Rocket Team is currently developing a new rocket architecture aimed at launching successively at an altitude of 3 km during the EuRoC 25 student rocketry competition, at an altitude of 9 km in 2026 and at an altitude of 30 km in 2028. Each new launch vehicle will benefit from the lessons learned from the previous launchers to gradually increase the performance and the reliability of the architecture. These launch vehicles are propelled by a pressure-fed regeneratively-cooled biliquid engine, aiming a thrust from 7.5 kN to 15 kN. The propellant tanks are pressurised with nitrogen at a pressure of around 60 bar coming from a COPV at around 300 bar. Passive COTS mechanical regulators are usually used in the industry, but they have significant drawbacks, mainly a very high mass and volume when a high nitrogen mass flow is needed, representing a significant performance penalty at the apogee of the rocket. Therefore, we are developing dynamical pressure regulators.

Project overview : In spring 2025, a proof of concept of a dynamical pressure regulator based on a ball valve was demonstrated in the context of a Semester Project. This Semester’s Project aim to continue this project by extensively testing this design to make it reliable and qualify it to be integrated in our next launch vehicle, Firehorn 2.

WHAT THE STUDENT(s) WILL DO:

- Review the design and the previous test data

- Prepare a test bench as close as possible to the launch vehicle configuration

- Test the existing dynamical pressure regulator at the Testing Facility of the EPFL Rocket Team

- Analyse the test data to understand its behaviour

- Improve the existing controller design

- Ensure the mechanical design and the controller are reliable

SKILLS INVOLVED:

- Testing

- Control

- Fluid mechanics

- Machining mechanical parts

STUDENT GAIN:

- Experience in testing a rocket propulsion device

- Experience in the control of a valve integrated in a high-pressure fluid system

- Use of a remotely controlled testing facility

- Mechanical design of a gear transmission

TASKS UNFOLDING:

- [2-3 weeks]: Design and literature review

- [3 weeks]: Test bench preparation

- [2 weeks]: Design and manufacturing

- [2 weeks]: Tests preparation

- [2 weeks]: Testing

- [2 weeks]: Documentation

Contacts: sven.profichet@epfl.ch

Supervisor: Markus Jäger

Status: TAKEN

PLASMA PROJECT

PROJECT DESCRIPTION

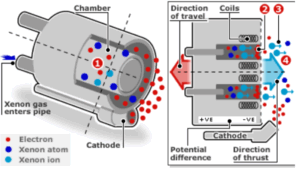

Context: The Hyperion Plasma Team focuses on electric propulsion. The Team has done research on the overall concept of the Hall Effect thruster (HET) and has come down to a preliminary design. In order to make a functional thruster, the plumbing (gas delivery system) and the design of the gas injector has to be done.

Project overview: The goal of the project is to design the plumbing of the thruster responsible for the gas injection into the chamber. The gas delivery system is constrained by weight and size limitations as well as material choices. The injector is also to be designed to maximise the gas volume in the chamber of the thruster.

Students with a background in courses such as Fluid Mechanics, Thermodynamics, or Mechanical Design may find this project particularly rewarding. However, willingness to learn is the most important qualities, the team will provide guidance and support throughout the project making it accessible to any motivated student.

WHAT THE STUDENT(s) WILL DO:

- Develop the plumbing of the thruster

- Design the gas injector

SKILLS INVOLVED:

- Fluid mechanics

- CAD

- Plumbing knowledge

- Prototyping

TASKS UNFOLDING:

- [2 weeks]: Literature review

- [3 weeks]: Develop the gas injector

- [3 weeks]: Develop a preliminary plumbing

- [3 weeks] : Prototyping

- [3 weeks] : Testing and iteration

Contacts: joseph.spender@epfl.ch

Supervisor: Maüsli

Status: TAKEN

Reference Links:

- Overview of Hall Effect thrusters : https://en.wikipedia.org/wiki/Hall-effect_thruster

- Review of Hall Thruster Neutral Flow Dynamics : https://pepl.engin.umich.edu/pdf/IEPC-2007-038.pdf

PROJECT DESCRIPTION

Context: The Hyperion Plasma team works on electric thruster. The team developed one thruster and is in the process of making another one. To make the testing more comprehensive and to qualify the thrusters, the team aims to develop a vibration testing rig dedicated to plasma thruster systems. This rig will allow the team to qualify the thrusters under dynamic loads similar to what a rocket launch may generate.

Project overview : The students shall first research and analyze what type of dynamic load they may be able to generate and if it is close to the dynamic loading experienced by a rocket during its launch. If this study is conclusive, the students will then move onto the design of the vibration rig which shall encompass all the required subsystems to make the final product standalone. This includes but is not limited to: control electronics, actuators, mechanical design, sensors, mechanical interfaces etc.

WHAT THE STUDENT(s) WILL DO:

- Control systems

- Electronics (Control, sensors, actuators)

- Mechanical design

SKILLS INVOLVED:

- Electronics

- CAD

- Control systems

- Space propulsion

TASKS UNFOLDING:

- [2 weeks]: Comprehensive system study

- [10 weeks]: Vibration rig design

- [2 weeks]: Qualification and validation of the system

Contacts: joseph.spender@epfl.ch

Supervisor: TBD

Status: AVAILABLE

Reference Links:

PROJECT DESCRIPTION

Context: Through the Hyperion plasma class (H-PC) project, the EPFL Rocket Team endeavors to develop, test, and qualify thrusters for space applications. A first set of technologies were selected: a pulsed plasma thruster (PPT) and a hollow cathode (HC).

A hollow cathode is a type of plasma source widely used in electric propulsion systems, particularly as an electron emitter in ion and Hall-effect thrusters, or as a standalone plasma source. It operates by heating a cathode insert (often impregnated with low-work-function materials) to emit electrons (this is called thermionic emission). A neutral gas, typically xenon, flows through the cathode, where the emitted electrons ionize the gas and sustain the discharge. Hollow cathodes are valued for their ability to provide high-current, long-lifetime electron emission in a compact and efficient package, making them critical components for spacecraft propulsion and plasma generation.

Basic knowledge of electronics is required for this project. Familiarity with circuit design or embedded systems is a plus, but not mandatory, we will provide technical support and resources to help you develop any additional skills needed.

Project Overview: With the initial study of the hollow cathode now complete, particular attention must be given to developing the auxiliary systems, namely the fluid distribution and the power electronics. This project focuses on the latter.

The student will first define the general architecture of the PPU circuit tailored to the hollow cathode’s operational requirements. They will then move on to selecting specific electronic components based on the most up-to-date performance specifications for ignition, steady-state operation, and current regulation. Finally, after receiving the components, the project will progress to the assembly phase, where the student is expected to build and qualify the PCB for use with the hollow cathode. The student is also expected to thoroughly document their work for posterity and future developments.

SKILLS INVOLVED:

- Electronic circuit design

- PCB design

- Vacuum proof technology

TASKS UNFOLDING:

- [4 weeks]: Circuit architecture definition

- [4 weeks]: Components selection and order

- [6 weeks]: Assembly and qualification

Contacts: joseph.spender@epfl.ch

Supervisor: Jean Michelle Sallese

Status: AVAILABLE

PROJECT DESCRIPTION

Context :The Hyperion plasma class (H-PC) project develops advanced electric propulsion systems for space. Our micro-newton thrust measurement bench, originally built for pulsed plasma thrusters (PPT), must be adapted for new configurations. Following the CDR for our hollow cathode (HC), we are preparing an electron gun based on its design. This project focuses on creating a hardware and software interface to integrate the electron gun, with potential extension to Hall Effect Thruster (HET) testing for greater bench versatility.

Skills from courses in Structural Mechanics, FEM, or CAD will be an asset. That said, this project is a great opportunity to develop these skills from scratch, with the help and knowledge of the Rocket Team.

Figure: Test bench and Hollow Cathode

Project overview : The student will create a versatile test bench interface to integrate a hollow cathode–based electron gun into our thrust measurement platform. This hands-on project covers the full process: defining electrical and data connections, selecting high-performance components, and developing smart control and measurement logic. Once built, the system will be put through rigorous integration tests to ensure it is experiment-ready, with the potential to adapt for other thruster types such as Hall Effect Thrusters.

WHAT THE STUDENT(s) WILL DO:

- Review existing test bench mechanical interfaces and constraints

- Study vacuum constraints

- Design custom mounts and adapters for the electron gun integration

- Document the interface design for future assembly and operation

SKILLS INVOLVED:

- Structural mechanics

- CAD

- FEM analysis

- Prototyping

TASKS UNFOLDING:

- [2 weeks]: Review of existing design

- [3 weeks]: Design of mounts

- [3 weeks]: FEM analysis

- [3 weeks] : Prototyping

- [3 weeks] : Manufacturing of final parts

Contacts: joseph.spender@epfl.ch

Supervisor: TBD

Status: AVAILABLE

Reference Links:

PROJECT DESCRIPTION

Context: The Hyperion Plasma team works on electric space propulsion. The Team developed one thruster and is in the process of making another one. In order to test the thrusters in vacuum condition, they need to be put in vacuum chambers with specific interfaces.

Project Overview:

The plasma thruster test bench is already operational and all required components are on hand. The custom interface design has been validated, and the next step is its fabrication, assembly, and qualification. The project will include machining of dedicated parts, building the electrical and fluidic connections tailored to the team’s needs, implementing optimized cable management, and integrating the gas feed into the chamber while ensuring full vacuum compatibility. In parallel, a literature review will benchmark the interface against international aerospace standards, guaranteeing that the system is both robust and compliant with state-of-the-art practices.

Students with a background in Electronics, Mechanical Design, will find this project particularly rewarding. Skills in machining, system integration, or practical lab work are an advantage, but not a requirement. Above all, motivation and a willingness to learn are what matter most, there will always be some coaches available to help you!

WHAT THE STUDENT(s) WILL DO:

- Design the electrical interface

- Design the plumbing

- Design the user interface for testing

SKILLS INVOLVED:

- CAD

- Electricity

- Rocketry plumbing

- Manufacturing

TASKS UNFOLDING:

- [2 weeks]: Literature review

- [3 weeks]: Electrical interface design

- [3 weeks] : Fluid interface design

- [4 weeks] : Manufacturing & Verification

Contacts: joseph.spender@epfl.ch

Supervisor: Maüsli

Status: AVAILABLE

Reference Links:

- A guide to preparing your vacuum system for thruster testing chambers : https://www.leybold.com/en-ie/knowledge/blog/vacuum-systems-for-thruster-testing