Are you an EPFL student and looking for a semester credited, Bachelors or Masters Project ? Look no further! We have something for you!

If you can’t find your dream project down here, but have an idea or would like to suggest your own project to do with us, we are open to suggestions! Feel free to contact us and we can talk about it.

2024 - 2025 SEMESTER PROJECTS

COMPETITION PROJECT

Payload

PROJECT DESCRIPTION

The EPFL Rocket Team is currently developing a new class of rockets aimed at launching at an altitude of 9km during the EuRoC 25 student rocketry competition. One of the requirements of this competition is that every launch vehicle needs to carry an experimental payload. The aim of this project is to develop the experimental payload that will be carried by the Firehorn 9 launch vehicle in 2025.

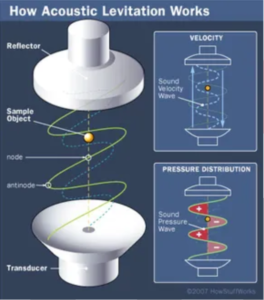

This payload will explore the possibilities of acoustic levitation using ultrasonic speakers during the different flight stages of the rocket to levitate a lightweight particle. Acoustic levitation is a technique that uses sound waves to levitate objects in the air without the need for physical supports.

During the second semester of the 2023 – 2024 school year, a functional prototype of this experiment has been developed and will be used as a starting point for this project.

This project consists in understanding the previous work done on the first prototype, on testing the design and on iterating on it until all the initial project requirements are verified. The testing campaign possibly includes inflight testing on a small rocket. When all is done, accomplished work will be documented to ensure future EPFL Rocket Team members can successfully integrate the final version of the experiment on the Firehorn rocket.

PROJECT UNFOLDING:

- [2 weeks]: Literature review and understanding the first prototype

- [8 weeks]: Testing and iterating on the prototype

- [3 weeks]: Verifying the initial project requirements

- [1 week]: Writing documentation

SKILLS NEEDED (or willing to learn):

- Electronics

- Coding (C)

- Prototyping and testing

STUDENT GAIN :

- Multidisciplinary project

- Learning tight requirements of aerospace engineering

- Gaining experience in prototyping and testing

Contact: samuel.wahba@epfl.ch

Supervisor: Sakar

Number of students: Available

PROJECT DESCRIPTION

The EPFL Rocket Team is currently developing a new class of rockets aimed at launching at an altitude of 9km during the EuRoC 25 student rocketry competition. In order to refine its technologies — simulations, engines, etc…, the ERT has relied on video recordings of the flights. As of now, the only operation-compatible means available for gathering such videos of the flights is a ground-based tracking system.

To broaden the range of data gathered during the missions, the ERT shall explore the use of camera modules directly embedded onboard the launch vehicle. A previous camera module crafted during the 2022 spring semester shall serve as the basis for this development.

This project consists in understanding the previous work done on the first prototype, on testing the design and on iterating on it until all the current project requirements are verified. The testing campaign possibly includes inflight testing on a small rocket. The accomplished work will be documented to ensure future EPFL Rocket Team members can successfully integrate the final version of the experiment on the Firehorn rocket.

PROJECT UNFOLDING:

- [2 weeks]: Literature review and understanding the first prototype

- [8 weeks]: Testing and iterating on the prototype

- [3 weeks]: Verifying the initial project requirements

- [1 week]: Writing documentation

SKILLS NEEDED (or willing to learn):

- Electronics

- Coding (C)

- Prototyping and testing

STUDENT GAIN :

- Multidisciplinary project

- Learning tight requirements of aerospace engineering

- Gaining experience in prototyping and testing

Contact: samuel.wahba@epfl.ch

Supervisor: Schmid

Number of students: Available

PROJECT DESCRIPTION

The EPFL Rocket Team is currently developing a new class of rockets aimed at launching at an altitude of 9km during the EuRoC 25 student rocketry competition. Additionally, the long term goal association is to reach an altitude of 100km with a liquid rocket. Knowing the stresses encountered by the rocket during the different flight regimes is of high interest as it will allow us to better design our next launch vehicles. Previous work on a similar project has already been done at the EPFL Rocket Team and can be a good starting point for this project.

The project consists in developing a module containing structural sensors and all their required supporting equipment such as the electronic and physical connections. The sensors need to measure the time history of accelerations and/or displacements at different locations on the rocket structure and to store the recorded data. Once a full working module has been developed, it needs to be tested and iterated upon until all project requirements are met.

PROJECT UNFOLDING:

- [2 weeks]: Literature review

- [4 weeks]: Design of 1st prototype

- [7 weeks]: Testing and design iterations

- [1 week]: Documentation

SKILLS NEEDED (or willing to learn):

- Electronics

- Understanding of vibrations

- Prototyping and testing

STUDENT GAIN :

- Learning tight requirements of aerospace engineering

- Gaining experience in prototyping and testing

Contact: samuel.wahba@epfl.ch

Supervisor: Villanueva

Number of students: Available

Structure

PROJECT DESCRIPTION

In order to dimension the structural parts of its rockets, the EPFL Rocket Team mainly uses structural simulations based on the Finite Element Method (FEM). Simulating an entire structural segment (like the one in the image below) is a difficult task, in part because the contacts between all of the different parts introduce a lot of nonlinearities. Moreover, using destructive testing to verify/validate simulations can be very expensive.

The aim of this project is to develop and build a modular workbench that can be easily moved, support the rocket and allow it to rotate around its cylindrical axis. It shall also enable each subsystem to be assembled and disassembled for integration operations. The bench shall be used for a range of rocket diameters and shall be used to display the rockets at exhibitions. Therefore, one of the main challenges of the project is to strike a balance between ergonomy, mechanical robustness and adaptability, all while staying within certain mass, volume and cost constraints.

A common method used in aerospace engineering to verify/validate large coupled FE models is to compare simulated and experimental modal analysis. By experimentally extracting the modal frequencies and mode shapes and correcting the FE models until the simulation results match with the experiment, it is possible to verify and correct large coupled FE models in a non-destructive manner.

This project has three goals: to establish a procedure/methodology to conduct experimental modal analysis, to establish a methodology to update FE models to match with experimental results, and to apply both methodologies on a rocket structural segment as a case study. The experimental modal analysis can be done using accelerometers and impulse excitation (hammer). The finite element model to validate will be created in ANSYS, which will also be used for the simulated modal analysis.

|

PROJECT UNFOLDING:

- [2 weeks]: Literature review

- [5 weeks]: Setting up experiment

- [2 weeks]: Experimental analysis

- [4 weeks]: FE Model correction

- [1 week]: Documentation

SKILLS NEEDED (or willing to learn):

- Structural dynamics

- Modal analysis

- Practical testing

- FE Simulations

- ANSYS (Mechanical)

STUDENT GAIN :

- Gaining experience on practical testing

- Gaining experience on simulation validation

- Gaining experience on structural dynamics

- Opportunity to work on a complex and very advanced structural engineering topic

Contacts: michael.fuser@epfl.ch

Supervisor: Villanueva , Bonhôte (HEIG)

Number of students: Available

PROJECT DESCRIPTION

The EPFL Rocket Team is currently developing a new class of rockets aimed at launching at an altitude of 9 km during the EuRoC 25 student rocketry competition and to launch at an altitude of 30 km in 2026. These launch vehicles are propelled by a biliquid engine. Two cylindrical aluminum tanks are located along the rocket length to store the propellant and oxidizer.

The in-flight accelerations experienced by the rocket can cause the fluid located inside the tanks to ‘move around’ (see image). This phenomenon is called sloshing and can lead to flight instabilities due to the movement of the center of mass of the rocket.

Additionally, vortices can sometimes appear at rocket tank outlets, just like in bathtubs or sinks when they are being emptied. These vortices can lead to instabilities in the mass outflow rate, which can have undesired effects on the propulsion system.

This project has three goals: to determine whether the current tanks design can experience sloshing, to determine whether they can experience vortex buildup at the outlet, and to identify mitigations to counter these phenomena.

To do this, experiments will be conducted under the supervision of the EPFL SCI-STI-MF group. Mockup tanks of the currently planned dimensions will be constructed and used for tests.

What the student will do :

- Construct the mockup tanks used for tests

- Perform the experimental test campaign

- Suggest and possibly test potential mitigations

STUDENT GAIN:

- Practical prototyping experience

- Experience as a test engineer

- Experience on notoriously difficult aerospace engineering/fluid mechanics problem

PROJECT UNFOLDING:

- [2 weeks]: Literature review

- [3 weeks]: Mockup tank production

- [8 weeks]: Test campaign

- [1 week]: Documentation

SKILLS NEEDED (or willing to learn):

- Prototyping

- Testing

- Fluid mechanics/dynamics

- Problem solving

Contacts: michael.fuser@epfl.ch

Supervisor: Farhat

Number of students: Available

PROJECT DESCRIPTION

The association plans to launch a sounding rocket named FIREHORN, that will fly at an altitude of 9 km, in October 2025. During the design phase, the structure team (competition project) turned to CFRP to manufacture its structural parts. In fact, composite materials are very popular in the aerospace industry because of their high strength to density ratio, enabling designs to be optimised to reduce weight. However, continuous fibre based composites are anisotropic, meaning that FEM simulations of such parts come with more uncertainties than for metallic parts.

In this context, this project aims to characterise the mechanical properties of the already produced CFRP rods.

The structure team has reserved CFRP rods for testing. The project has three goals: to verify that these rods comply with the load requirements, to validate the finite element model of their mechanical behaviour and to introduce a testing methodology for CFRP parts within the association.

The student will perform mechanical tests such as tensile and bending tests. Similar tests will be done under cryogenic conditions as the carbon rods of the rocket will be in contact with liquid oxygen (-183°C) tanks during the launch. Lastly, destructive buckling tests on an entire structural segment of the rocket will be performed.

What the student will do :

- Literature review on mechanical testing

- Test specification and procedure

- Dogbones and other normalised sample design and production (workshop)

- Tensile and bending tests

- Buckling tests

- Results comparison with numerical models

- Friction coefficient with aluminium measurement

- Writing a general methodology for mechanical tests

STUDENT GAIN:

- to work with norms (ISO/DIN/ASTM)

- to plan and organise practical experiments

- to perform mechanical tests and analyse results

PROJECT UNFOLDING:

- [2 week]: Literature review

- [2 weeks]: Simulations

- [2 weeks]: Testing samples production

- [6 weeks]: Mechanical tests

- [2 weeks]: Results analysis and reports

SKILLS NEEDED (or willing to learn):

- Anisotropic solid mechanics

- Composites (CFRP)

- Lab work

- Static simulations

- Experiments planning

Contacts: michael.fuser@epfl.ch

Supervisor: Farhat

Number of students: Available

PROJECT DESCRIPTION

The association is currently designing a sounding rocket about 5.4 m long with a dry mass of about 80 kg. The next rockets will be even longer and heavier. Holding and manipulating such vehicles requires appropriate equipment. As part of a semester project, a first version of a modular workbench was designed to allow the assembly and display of rockets. Today’s design fulfills the two requirements. It supports the rocket and allows the latter to turn around its main axis. Nonetheless, this prototype still needs to be upgraded for further functionalities.

The aim of this project is to finalise the design of the current supports. The workbench shall be built to allow operators to perform assembly and testing operations on different segments of the rockets produced by the end of the project. Moreover, the students will implement a displacement mechanism to these supports.

What the student will do:

- Literature review

- Mechanical design

- Manufacturing

- Design validation through practical tests

STUDENT GAIN:

The student will learn how to develop a modular structure that complies with strict requirements. The student will go through the parts design phase, then static and dynamic simulations, before moving on to manufacturing and testing.

PROJECT UNFOLDING:

- [6 weeks]: Conception

- [2 weeks]: Material order

- [4 weeks]: Manufacturing

- [2 weeks]: Tests

SKILLS NEEDED (or willing to learn):

- General mechanical knowledge

- CAD

- Manufacturing

Contacts: michael.fuser@epfl.ch

Supervisor: Soubielle

Number of students: Available

PROJECT DESCRIPTION

The EPFL Rocket Team is currently developing a new class of rockets aimed at launching at an altitude of 9 km during the EuRoC 25 student rocketry competition and to launch at an altitude of 30 km in 2026. To carry the structural loads from the engine to the top of the rocket, an internal structure has been designed with carbon fibers rods that carry the main loads and aluminum anti buckling rings (ABR) that act as an anti-buckling pivot point.

Designing the anti buckling rings is a challenging task. Predicting the loads they encounter requires costly destructive testing, or complex highly non-linear simulations. Additionally, these rings also need to act as a fixation/interface for non structural parts, such as plumbing or electrical wires. Finally, because between 5 and 10 ABRs are located throughout the rocket, there is a high incentive to optimize their mass.

This project has two goals: to establish a methodology to design and dimension the ABRs under certain constraints and objectives, and to apply this methodology to propose different design options. To do this, a rigorous design methodology has to be applied, starting from the listing of objectives, constraints and free variables (product definition), and ending at the technical drawing.

Prototyping is also encouraged.

What the student will do :

- Product definition phase: Understanding the project requirements, objectives, constraints and free variables

- Conceptual design phase: Defining and evaluating several design options

- Embodiment phase: Simulation, analysis and refinement of selected options

- Detailed design phase: Optimization and technical drawings

STUDENT GAIN:

- Opportunity to apply rigorous design methodology

- Experience in applied mechanical design

- Opportunity to design a part that will fly in a rocket

PROJECT UNFOLDING:

- [2 weeks]: Literature review

- [2 weeks]: Product definition

- [3 weeks]: Conceptual design

- [3 weeks]: Embodiment

- [4 weeks]: Detail design

SKILLS NEEDED (or willing to learn):

- Applied mechanical design

- Structural mechanics

- Structural Simulations

- General mechanical engineering

Contacts: michael.fuser@epfl.ch

Supervisor: Soubielle, Schiffmann

Number of students: Available

Flight Dynamics

PROJECT DESCRIPTION

The EPFL Rocket Team is currently developing a new class of rockets aimed at launching at an altitude of 9 km during the EuRoC 25 student rocketry competition and to launch at an altitude of 30 km in 2026. These launch vehicles will fly in the supersonic regime and need to be dimensioned according to the thermomechanical loads encountered by the different rocket parts during flight. Computational Fluid Dynamics (CFD) is one of the tools used at the EPFL Rocket Team to predict such loads. The current rocket being developed has external plumbing and wires running along a certain portion of the external airframe. To reduce the drag caused by these external elements, a carbon fiber aerocover will be used (see image).

This project consists in the aerodynamic design and CFD analysis of this aerocover. For the design part, the constraints are already defined and work only must be done on the aerodynamic shape of the aerocover. For the CFD part, the thermomechanical loads applied on the aerocover under different flight conditions must be extracted.

This project consists in the aerodynamic design and CFD analysis of this aerocover. For the design part, the constraints are already defined and work only must be done on the aerodynamic shape of the aerocover. For the CFD part, the thermomechanical loads applied on the aerocover under different flight conditions must be extracted.

To do this, an internal procedure describing how to perform similar simulations will be used as a starting point. Because of the high computational cost of these simulations, High Performance Computing (HPC) clusters provided by EPFL will be used.

What the student will do :

- Perform the aerodynamic design of the aerocover

- Perform CFD simulations according to the given parameters

- Perform CFD simulations on a geometry without any aerocover to quantify the drag reduction caused by it

- Perform post-processing of the generated data to verify the results

Use the HPC clusters provided by EPFL

Use the HPC clusters provided by EPFL

STUDENT GAIN:

- Opportunity to practice CFD on an aerospace engineering project

- Working with HPC resources

- Experience as a simulations engineer

PROJECT UNFOLDING:

- [3 weeks]: Aerocover design

- [7 weeks]: Simulations

- [3 weeks]: Postprocessing activities

- [1 week]: Documentation

SKILLS NEEDED (or willing to learn):

- (Compressible) Fluid Mechanics

- Computational Fluid Dynamics

- Simulations

- ANSYS (Fluent, Workbench)

- Aerodynamics

Contacts: michael.fuser@epfl.ch

Supervisor: Boujo, Noca

Number of students: Available

PROJECT DESCRIPTION

The EPFL Rocket Team is currently developing a new class of rockets aimed at launching at an altitude of 9 km during the EuRoC 25 student rocketry competition and to launch at an altitude of 30 km in 2026. These launch vehicles will fly in the supersonic regime and need to be dimensioned according to the thermomechanical loads encountered during flight. Computational Fluid Dynamics (CFD) is one of the tools used at the EPFL Rocket Team to predict such loads.

This project consists in performing CFD simulations in ANSYS Fluent to predict the loads encountered during the 30 km flight. To do this, an internal procedure describing how to perform such simulations will be followed. This makes this project a great opportunity to learn CFD. Because of the high computational cost of these simulations, High Performance Computing (HPC) clusters provided by EPFL will be used.

What the student will do :

- Perform CFD simulations of a supersonic rocket according to the given parameters and methodology

- Perform post-processing of the generated data to verify the results

- Use the HPC clusters provided by EPFL

- Extract different qualitative and quantitative results, such as the peak temperature encountered during flight, or the location of shockwaves

STUDENT GAIN:

- Excellent opportunity to learn/practice CFD

- Working with HPC resources

- Experience as a simulations engineer

PROJECT UNFOLDING:

- [2 weeks]: Creating the CAD

- [2 weeks]: Initial Mesh

- [3 weeks]: First simulations run

- [3 weeks]: Mesh study

- [3 weeks]: Postprocessing activities

- [1 week]: Documentation

SKILLS NEEDED (or willing to learn):

- (Compressible) Fluid Mechanics

- Computational Fluid Dynamics

- Simulations

- ANSYS (Fluent, Workbench)

Contacts: michael.fuser@epfl.ch

Supervisor: Boujo, Noca

Number of students: Available

Recovery

PROJECT DESCRIPTION

The EPFL Rocket Team’s goal is to fly a rocket which will reach the Karman line by 2030. One critical stage of the mission is the recovery of the rocket. The rocket team has been working on recovery systems since it first started, however our target apogee has never been above 9km. Given that the target apogee altitude is considerably higher than any previous missions, the operational environment requirements have also changed.

Following the change of requirements, several assemblies of the recovery subsystem’s design need to change. One such assembly is the parachute deployment system, which is responsible for ejecting the parachute out of the rocket and away from the rocket’s wake.

The goal of this project is to develop the preliminary design for an active parachute deployment system which will be used for the spaceshot rocket.

What the student will do :

- State of the art analysis

- Definition of performance metrics

- Establishing the feasibility of the recommended solution

- Defining operating conditions

- Risk Assessment

- Estimate manufacturing, production and operating costs

- Identification of interfaces with other subsystems and other assemblies within the recovery subsystem

- 3D modeling of the preliminary design

STUDENT GAIN:

- Mechanical Design

- CAD

- developing sizing models

- State-of-the-art analysis

- Risk assessment

- Introduction to recovery systems for aerospace applications

- Introduction to ECSS

PROJECT UNFOLDING:

- [3 weeks]: General research and state of the art analysis

- [1 weeks]: Establish performance metrics and selection of system concept

- [5 weeks]: Preliminary design: sizing, risk assessment, operating conditions, cost estimations

- [4 weeks]: CAD, interface identification, documentation

Contacts: ryan.svoboda@epfl.ch

Supervisor: Pierre-Alain Mäusli

Number of students: Available

PROJECT DESCRIPTION

The EPFL Rocket Team’s goal is to fly a rocket which will reach the Karman line by 2030. One critical stage of the mission is the recovery of the rocket. The rocket team has been working on recovery systems since it first started, however our target apogee has never been above 9km. Given that the target apogee altitude is considerably higher than any previous missions, the operational environment requirements have also changed.

Following the change of requirements, we would like to reexamine different recovery system architectures.

The goal of this project is to develop the preliminary design for a guided parachute deployment system which could be used for the spaceshot rocket.

What the student will do :

- State of the art analysis

- Definition of performance metrics

- Establishing the feasibility of the recommended solution

- Defining operating conditions

- Risk Assessment

- Estimate manufacturing, production and operating costs

- Identification of interfaces with other subsystems and other assemblies within the recovery subsystem

- 3D modeling of the preliminary design

STUDENT GAIN:

- Mechanical Design

- CAD

- developing sizing models

- State-of-the-art analysis

- Risk assessment

- Introduction to recovery systems for aerospace applications

- Introduction to ECSS

PROJECT UNFOLDING:

- [3 weeks]: General research and state of the art analysis

- [1 weeks]: Establish performance metrics and selection of system concept

- [5 weeks]: Preliminary design: sizing, risk assessment, operating conditions, cost estimations

- [4 weeks]: CAD, interface identification, documentation

Contacts: ryan.svoboda@epfl.ch

Supervisor: Alireza Karimi

Number of students: Available

PROJECT DESCRIPTION

The EPFL Rocket Team’s goal is to fly a rocket which will reach the Karman line by 2030. One critical stage of the mission is the recovery of the rocket. The rocket team has been working on recovery systems since it first started, however our target apogee has never been above 9km. Given that the target apogee altitude is considerably higher than any previous missions, the operational environment requirements have also changed.

Following the change of requirements, several assemblies of the recovery subsystem’s design will need to change. Thus we would like to start the mission analysis, needs identification and feasibility study (ECSS Project Phase 0 and A) for the recovery subsystem.

The project’s aim is to provide the first iteration of the systems engineer’s responsibilities during phase 0 and phase A (as defined by ECSS) of a project. The deliverables include: preliminary technical requirements specifications, system model, work breakdown structure and function tree, risk assessment document.

What the student will do :

- Characterisation of mission

- Establish the needs, expected performance and dependability and safety goals

- Assessment of operating constraints

- Identification of possible system concepts

- Picking a system concept

- Modeling the chosen system concept

- Establish a preliminary list of requirements

STUDENT GAIN:

Systems engineering

Requirement engineering

Interface management

System modeling

PROJECT UNFOLDING:

- [3 weeks]: General research and state of the art analysis

- [3 weeks]: Identification and characterization of the mission needs, expected performance, dependability and safety goals and mission operating constraints

- [4 weeks]: Establish function tree, system modeling

- [3 weeks]: Establish technical requirement specification

Contacts: ryan.svoboda@epfl.ch

Supervisor: TBD

Number of students: Available

Ground Segment

PROJECT DESCRIPTION

The EPFL Rocket Team is currently developing a new class of rockets designed to reach altitudes of up to 30km. Firehorn’s maiden flight is scheduled to take place during the 2025 European Rocketry Competition (EuRoC), with a target apogee set at 9km. Until now, all ERT launch vehicles have relied on EuRoC’s own launch rails. These, however, will prove insufficient as our vehicles increase in size and weight.

The EPFL Rocket Team has therefore decided to explore in-house options for a launch rail design capable of supporting operations for altitudes of up to 30km. This rail design shall be made compatible with Firehorn-class launch vehicles.

The aim of this project is to produce a scalable design adapted for various altitude targets. Furthermore, since the rocket is to be secured to the rail horizontally before raising the whole assembly, a “raising mechanism” shall be included in the designs.

STUDENT GAIN:

- Multidisciplinary project

- Literature review

- Mechanical design

- Manufacturing

- Design validation through practical tests

- The student(s) will learn how to develop a scalable structure that complies with strict requirements. They will go through the parts design phase, then static and dynamic simulations, before moving on to manufacturing and testing.

SKILLS NEEDED:

- General mechanical knowledge

- CAD

- Manufacturing

PROJECT UNFOLDING:

- [6 weeks]: Conception

- [2 weeks]: Material order

- [4 weeks]: Manufacturing

- [2 weeks]: Tests

Contacts: samuel.wahba@epfl.ch

Supervisor: Soubielle

Number of students: Available

ICARUS PROJECT

PROJECT DESCRIPTION

The EPFL Rocket Team is developing a Vertical Takeoff, Vertical Landing (VTVL) hopper named Icarus. Its aim is to perform “hops” : brief, low-altitude (maximum 10 meters), vertical trajectories with hovering time at the apogee. It has a wet mass of around 80kg while being powered by a 1 kN bi-liquid rocket engine. The gimbal will carry and guide this rocket engine to achieve Thrust Vector Control, crucial for steering and stabilizing the hopper. The gimbal has already been designed and has had a paper presented at IAC23. The next step is to conduct comprehensive testing and validation to ensure the gimbal system meets the performance requirements for the Icarus project.

In the context of thrust vector control for a bi-liquid rocket engine, the gimbal system plays a crucial role in steering the Hopper. This semester project will focus on the detailed characterization, extensive testing, precise control, and thorough validation of the gimbal system.

The initial phase involves measuring the mechanical properties of the gimbal system, such as stiffness, damping, and response time, to inform the design of accurate control algorithms. Following this, the gimbal system will undergo static and dynamic testing to verify its response to control inputs and simulate real operating conditions. The tests will be carried out with a traction machine as well as a vibration testing machine. This aims to identify any potential weaknesses or failure modes. The final phase is validation, integrating the gimbal system with the hopper’s flight computer and conducting Static Fire Tests (SFTs) and gimbaled SFTs to ensure the system operates as intended under realistic flight conditions.

SKILLS NEEDED (or that you are willing to learn)

- Robotics

- Mechanical Design

- Control Systems

TASKS UNFOLDING:

- [4 weeks]: Initial Vibration and static tests

- [6 weeks]: Characterisation and control

- [4 weeks]: Gimbaled & static fire test

Contact: guillaume.hueber@epfl.ch

Supervisor: Mohamed Bouri

Availability: TAKEN

PROJECT DESCRIPTION

The EPFL Rocket Team is developing a Vertical Takeoff, Vertical Landing (VTVL) hopper named Icarus. Its aim is to perform “hops” : brief, low-altitude (maximum 10 meters), vertical trajectories with hovering time at the apogee. It has a wet mass of around 80 kg while being powered by a 1 kN bi-liquid rocket engine. Following the successful design and manufacturing of the hopper last semester, the next critical step is the development of a robust launch pad.

The launch pad must be designed to withstand the high temperatures and forces generated by the rocket’s exhaust during both static and dynamic testing. It shall support the Vertical Static Fire Tests (VSFT) of the vehicle, providing a stable and secure base for the Hopper. The pad should be lightweight or easily placed into position while being designed to safely land the Hopper in case of a fall. Additionally, the platform should incorporate sensors to monitor fuel levels in the tanks during the filling process.

SKILLS NEEDED (or that you are willing to learn)

- Mechanical design

- Simulations & prototyping

- Machining / welding

TASKS UNFOLDING:

- [5 weeks]: Design and simulations

- [4 weeks]: Prototyping

- [5 weeks]: Manufacturing

Contact: guillaume.hueber@epfl.ch

Supervisor: Pierre-Alain Mäusli

Availability: Available

PROJECT DESCRIPTION

The EPFL Rocket Team is developing a Vertical Takeoff, Vertical Landing (VTVL) hopper named Icarus. Its aim is to perform “hops” : brief, low-altitude (maximum 10 meters), vertical trajectories with hovering time at the apogee. In order to achieve thrust vectoring capabilities, Icarus has been developing a gimbal system to redirect the engine’s thrust, thereby enabling control over the yaw and pitch of the vehicles. This, however, leaves roll – rotations around the vertical axis – completely unchecked.

The objective of this semester project is to test the reaction control wheel on a drone version of the Hopper which is already built. This allows for low impact testing – if the drone crashes, it can easily be repaired. Data from these tests would provide insights into the wheel’s torque generation, response time, and impact on overall stability, allowing for fine-tuning and optimization before implementation on the actual Hopper.

Implementing the reaction control wheel on the Hopper offers several advantages, such as enhanced stability and precise attitude control, which are critical for a safe flight and landing maneuvers. Once proven effective on the Hopper, the technology can be translated and integrated into more conventional rockets, improving their stability and control.

SKILLS NEEDED (or that you are willing to learn)

- Mechanical design

- Quick prototyping

- Testing

TASKS UNFOLDING:

- [5 weeks]: Design and Prototyping

- [4 weeks]: Manufacturing

- [4 weeks]: Testing

Contact: guillaume.hueber@epfl.ch

Supervisor: Sébastien Soubielle

Availability: Available

PROJECT DESCRIPTION

The EPFL Rocket Team is developing a Vertical Takeoff, Vertical Landing (VTVL) hopper named Icarus. Its aim is to perform “hops” : brief, low-altitude (maximum 10 metres), vertical trajectories with hovering time at the apogee. It has a dry mass of around 75kg while being powered by a 1 kN bi-liquid rocket engine. Following the successful design and manufacturing of the hopper last semester, the next critical step is the development of a robust way to move around the hopper.

The Hopper moving platform aims to facilitate the easy and quick setup of the Hopper. It allows for a significant reduction in the Hopper’s footprint, making transportation more efficient. The platform is designed with wheels for mobility and must attach securely to the Hopper to ensure safe transportation.

The Hopper moving platform should be constructed from robust materials to ensure durability and stability, with a user-friendly design allowing quick and effortless attachment and detachment. Safety features such as wheel locks and secure attachments are essential to prevent movement during transit. The platform should also be designed to fold or disassemble for compact storage and be resistant to environmental factors like moisture, dust, and temperature variations for reliable performance in various conditions.

SKILLS NEEDED (or that you are willing to learn)

- Mechanical design

- Simulations & prototyping

- Machining

TASKS UNFOLDING:

- [5 weeks]: Design and simulations

- [4 weeks]: Prototyping

- [5 weeks]: Manufacturing

Contact: guillaume.hueber@epfl.ch

Supervisor: Sebastien Soubielle

Availability: Available

HYPERION PROJECT

Plasma

PROJECT DESCRIPTION

Through the Hyperion plasma class (H-PC) project, the EPFL Rocket Team endeavors to develop, test and qualify thrusters for space applications. A first set of three technologies were elected: a pulsed plasma thruster (PPT), an arcjet and a hall-effect thruster (HET).

Arcjet thrusters are a type of electrothermal propulsion systems where a gas is ionized through the discharge of an electrical arc created in between two parts of a reaction chamber. This ionization increases the energy of the gas creating important exhaust velocities. Those thrusters are mainly used in station-keeping, orbit maintenance and trajectory adjustments in satellites as well as in deep space missions due to their high specific impulse and good efficiency. Although thrust is usually low compared to chemical systems, these engines have played, and continue to play, an important role in space exploration.

After a successful preliminary study of the Arcjet thruster that yielded an initial design and preliminary simulation results, it became clear that further simulation work was required to better understand and approximate the thruster’s thermal behavior. This project revolves around confirming the preliminary results obtained during past work and verifying them through empirical formulas. Once confidence in previous work is improved, the project will move on to further improving the computational model. The emphasis will be put on estimating solid temperatures and fluid dynamics inside the thruster.

PROJECT UNFOLDING:

- [1 week]: Software exploration

- [2 weeks]: Initial results verification

- [11 weeks]: Simulation study and reports

SKILLS NEEDED (or that you are willing to learn)

- Computational fluid dynamics (CFD)

- Electromagnetic simulations

- Eagerness to learn complex industry-leading software (ANSYS MAXWELL and ANSYS FLUENT)

Contact: matthieu.tonneau@epfl.ch

Supervisor: Pierre-Alain Mäusli

Availability: Available

PROJECT DESCRIPTION

Through the Hyperion plasma class (H-PC) project, the EPFL Rocket Team endeavors to develop, test and qualify thrusters for space applications. A first set of three technologies were elected: a pulsed plasma thruster (PPT), an arcjet and a hall-effect thruster (HET).

Arcjet thrusters are a type of electrothermal propulsion systems where a gas is ionized through the discharge of an electrical arc created in between two parts of a reaction chamber. This ionization increases the energy of the gas creating important exhaust velocities. Those thrusters are mainly used in station-keeping, orbit maintenance and trajectory adjustments in satellites as well as in deep space missions due to their high specific impulse and good efficiency.

Although thrust is usually low compared to chemical systems, these engines have played, and continue to play, an important role in space exploration.

Although thrust is usually low compared to chemical systems, these engines have played, and continue to play, an important role in space exploration.

The initial design of the Arcjet thrusters allows for a number of mechanisms to be implemented in order to allow for extensive performance testing. One of them is to enable axial repositioning of the center electrode during operation. This project will focus on designing and testing this mechanism. Because of the nature of the thruster, this mechanism should be vacuum compatible and maintain the electrical connection while being properly insulated. The axial range of motion is set at [10] mm and a decent degree of precision is required. Further requirements are defined in the respective requirements file.

PROJECT UNFOLDING:

- [1 week]: Design exploration

- [3 weeks]: Mechanical system dimensioning

- [1 week]: Mechanical system selection

- [1 week]: Actuator selection

- [5 weeks]: Mechanical system design

- [3 weeks]: Design verification and testing

SKILLS NEEDED (or that you are willing to learn)

- Mechanical design

- Robotics

- Space mechanisms

Contact: matthieu.tonneau@epfl.ch

Supervisor: Pierre-Alain Mäusli

Availability: Available

PROJECT DESCRIPTION

Through the Hyperion plasma class (H-PC) project, the EPFL Rocket Team endeavors to develop, test and qualify thrusters for space applications. A first set of three technologies were elected: a pulsed plasma thruster (PPT), an arcjet and a hall-effect thruster (HET).

In spacecraft propulsion, a Hall-effect thruster (HET) is a type of ion thruster in which the propellant is accelerated by an electric field. Hall-effect thrusters use a magnetic field to limit the electrons’ axial motion and then use them to ionize propellant, efficiently accelerate the ions to produce thrust, and neutralize the ions in the plume. The Hall-effect thruster is classed as a moderate specific impulse (1,600 s) space propulsion technology and has benefited from considerable theoretical and experimental research since the 1960s.

After a successful exploration of the physics of the hall effect thruster through a simulation project during the semester of Spring 2024, the EPFL Rocket Team now wishes to move onto the next phase of the development of this space propulsion technology. This project will focus first on assessing the key performance metrics for said thruster while surfacing a complete and thorough set of requirements. The student is expected to perform a thorough evaluation of the feasibility of further developments from a systems engineering point of view. Once this is done, the student will then move onto dimensioning the thruster and creating an initial CAD design applying previously derived requirements. Although not as extensive, the student is expected to bring the HET thruster concept to a similar level of maturity as to what the Arcjet thruster is currently at.

PROJECT UNFOLDING:

- [5 week]: System and requirements definition

- [2 weeks]: Preliminary dimensioning

- [7 weeks]: Initial mechanical design

SKILLS NEEDED (or that you are willing to learn)

- Systems engineering

- Mechanical design

- Design for space application

Contact: matthieu.tonneau@epfl.ch

Supervisor: Markus Jäger

Availability: Available

PROJECT DESCRIPTION

Through the Hyperion plasma class (H-PC) project, the EPFL Rocket Team endeavors to develop, test and qualify thrusters for space applications. A first set of three technologies were elected: a pulsed plasma thruster (PPT), an arcjet and a hall-effect thruster (HET).

Arcjet thrusters are a type of electrothermal propulsion systems where a gas is ionized through the discharge of an electrical arc created in between two parts of a reaction chamber. This ionization increases the energy of the gas creating important exhaust velocities. Those thrusters are mainly used in station-keeping, orbit maintenance and trajectory adjustments in satellites as well as in deep space missions due to their high specific impulse and good efficiency. Although thrust is usually low compared to chemical systems, these engines have played, and continue to play, an important role in space exploration.

The initial design of the arcjet thruster allows for a number of variables to be tested. Because of the highly empirical nature of previous arcjet developments, pinpointing exact values for optimal performance proved difficult. In order to derive peak performance characteristics, the testing setup will require a modular power processing unit to power the arcjet. With that experience, the following arcjet iterations will be able to be optimized according to specifications derived using the PPU.

The student will first define the general architecture of the circuit. He/She will then move onto selecting the specific electronic components using the most up-to-date performance specifications. Finally, after reception of the components, the project will move to the assembly phase where the student is expected to build and qualify the PCB for use with the arcjet thruster.

.

PROJECT UNFOLDING:

- [4 weeks]: Circuit architecture definition

- [4 weeks]: Components selection and order

- [6 weeks]: Assembly and qualification

SKILLS NEEDED (or that you are willing to learn)

- Power electronics

- PCB design

- Design for space applications

Contact: matthieu.tonneau@epfl.ch

Supervisor: TBD

Availability: Available

PROJECT DESCRIPTION

Through the Hyperion plasma class (H-PC) project, the EPFL Rocket Team endeavors to develop, test and qualify thrusters for space applications. A first set of three technologies were elected: a pulsed plasma thruster (PPT), an arcjet and a hall-effect thruster (HET). While the later 2 still require some further developments and research before coming to maturity, the PPT is already built in the form of a prototype. While some preliminary testing of this model is expected to happen as early as the semester of autumn 2024, it becomes apparent that further testing will require a defined and thorough methodology in order for the obtained results to be satisfactory and up to quality standards.

This project entails to define a comprehensive methodology for testing plasma-powered thrusters in a vacuum environment. The derived method should be broad in its application field but ought to be able to be tailored for specific applications. In that sense, the testing variables, the expected outcomes and the environmental constraints may change from one thruster to another, however the general approach should stay the same. A strong emphasis should be put on testing safety, both of the human operators and of the external partner facilities. Once the methodology is developed, the student shall perform a case study on the PPT to verify the quality of the methodology.

PROJECT UNFOLDING:

- [10 weeks]: Methodology definition

- [4 weeks]: Case study

SKILLS NEEDED (or that you are willing to learn)

- Systems engineering

- Protocol engineering

- Vacuum applications

Contact: matthieu.tonneau@epfl.ch

Supervisor: Gilles Feusier

Availability: Available

Hyperion

Stay Tuned!