The recruitment event will take place on the 26th of September 2024 in the CO1 Hall from 19h. If you’re interested in joining one of our projects or semester project we recommend being there. You’ll have the opportunity to meet the team leaders and heads of project, which will present the different projects and the workload in greater details.

Semester Projects

If you would like to join one of our semester projects, you will find the list by clicking on the following link. The Semester projects shown here are related to the research projects (Icarus and Hyperion) as well as our competition project.

MANAGEMENT

Our sponsorship team is responsible for seeking out new sponsors while developing the relationship we have with our current partners. This requires good interpersonal skills and some sales and negotiation skills. But we are also looking for students, experienced or not, who are motivated to find new ideas to make our sponsoring services as attractive as possible. This team is led by the Sponsoring Vice-President.

Skills required: French and English, German a real plus. All sections of EPFL, HEC or HEIG-VD welcome.

Our communication team is responsible for promoting the association on our social networks, on the EPFL campus and in the press. It is composed of editors, a community manager and also photographers, videographers and webmasters. This team is led by the Communication Vice-President.

Skills required for the writing team: Flawless French, good knowledge of English, and good interpersonal skills. Good extension skills. All sections of EPFL, UNIL and SAWI welcome.

Skills required for the visuals team: sense of image, skills in photo and/or video editing. All sections of EPFL, ECAL, CEPV and other schools/universities welcome.

Our logistics team is in charge of organizing our events, travels and manages the day-to-day logistics. You must be an organized person and have a car driving license. This is an opportunity to learn management and develop cross-functional skills. This team is led by the Logistics Vice-President.

Skills required: All sections of EPFL, HEC or HEIG-VD welcome. Driving license required.

Our Human Ressources team is in charge of organizing events alongside the Logistics team, leads interviews for new members, plans events to vivify the association and grants access to our different services. Finally you will also be able to organize workshops to help other members acquire soft-skills. This team is led by the HR Vice-President.

Skills required: All sections of EPFL, HEC or HEIG-VD welcome.

Vice-presidency

The role of the Communication Vice-President is to lead the communication team, it comes with responsabilities as well as a seat in the committee. It requires a good organization, being able to delegate work and work as a team. You should also be comfortable with social medias.

Skills required: Flawless French, good knowledge of English, and good interpersonal skills. Good extension skills. All sections of EPFL, UNIL and SAWI welcome.

The role of the Logistics Vice-President is to lead the logistics team, it comes with responsabilities as well as a seat in the committee. It requires a overall view of the association and events taking place, being able to delegate work, being organized and work as a team.

Skills required: All sections of EPFL, HEC or HEIG-VD welcome. Driving license required.

The role of the Human Ressources Vice-President is to lead the HR team, it comes with responsabilities as well as a seat in the committee. It requires a overall view of the association and events taking place, being able to delegate work, being organized and work as a team. You should also hear the other members out and come up with solutions to the committee.

Skills required: All sections of EPFL, HEC or HEIG-VD welcome.

COMPETITION PROJECT

EuRoC 2023

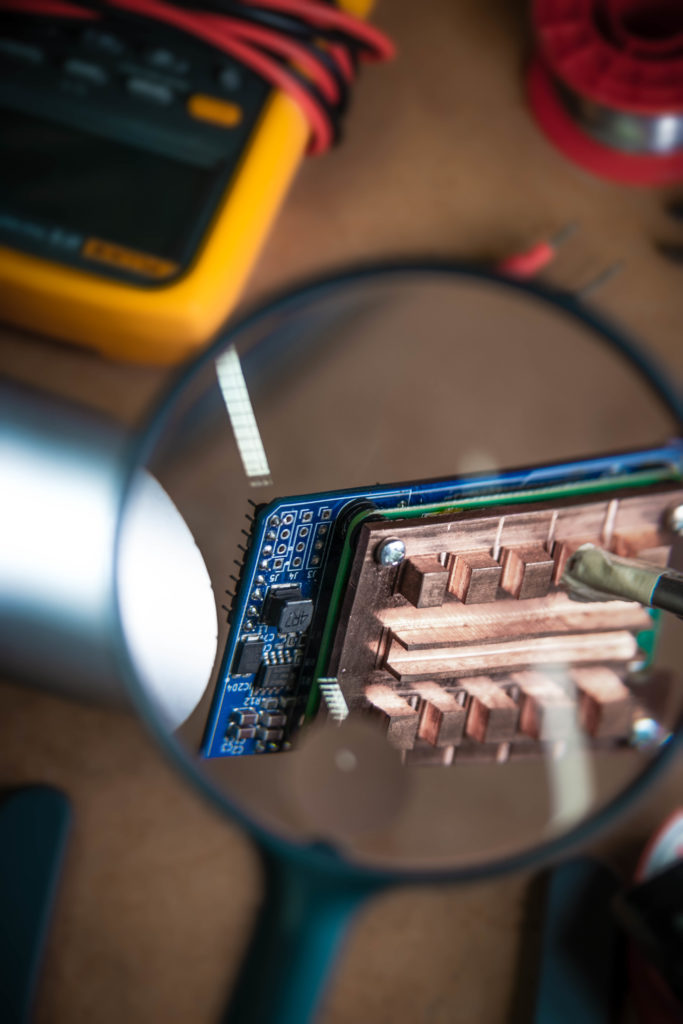

Avionics

The Avionics allows the rocket to figure out and send to the ground information on the rockets status (position, speed, acceleration, etc).

The Avionics is also in charge of triggering recovery events to release the parachute at the right time.

And finally, according to the engine used, it can also act as intermediary between propulsion systems and some of the ground segment systems.

Available Roles:

The Avionics subsystem is in charge of the design of the electronics and the software of the rocket. In this context, we are looking for a hardware electrical engineer.

Responsibilities:

- Design and/or upgrade the already existing avionics boards.

- Manufacture, plan and execute the testing of the PCBs.

- Coordinate with the other members also in charge of the hardware.

- Update and create the documentation for your work.

- Attend and prepare slides for the weekly meetings.

Experience in the following is a plus:

- PCB Design

- Communication protocols

- Electronics

A general idea of the years unfolding:

- [S1-W4]: Start of the pcb design

- [S1-W11]: Preliminary design review

- [S2-W1]: Start of the pcb manufacturing

- [S2-W8]: Critical design review

- [End of S2+Summer until EuRoC]: Testing and rocket integration

The Avionics subsystem is in charge of the design of the electronics and the software of the rocket. To be able to communicate with the ground, we are in need of an RF engineer.

Responsibilities:

- Design and manufacture antennas for the rocket.

- Design and manufacture of RF circuits.

- Coordinate with the other avionics members in charge of the hardware.

- Update and create the documentation for your work.

- Attend and prepare slides for the weekly meetings.

Experience in the following is a plus:

- Antenna design

- Radio-frequency engineering

- PCB design

A general idea of the years unfolding:

- [S1-W4]: Start of the project

- [S1-W11]: Preliminary design review

- [S2-W8]: Critical design review

- [End of S2+Summer until EuRoC]: Testing and rocket integration

The Avionics subsystem is in charge of the design of the electronics and the software of the rocket. In this context, we are looking for a software engineer.

Responsibilities:

- Optimize and update the current software.

- Coordinate with the other members also in charge of the software.

- Update and create the documentation for your work.

- Attend and prepare slides for the weekly meetings.

Experience in the following is a plus:

- Embedded systems

- C/C++

A general idea of the years unfolding:

- [S1-W4]: Start of the project

- [S1-W11]: Preliminary design review

- [S2-W8]: Critical design review

- [End of S2+Summer until EuRoC]: Testing

The Avionics subsystem is in charge of the design of the electronics and the software of the rocket. To be able to fit the hardware in the rocket, we are looking for a mechanical engineer to design the avionics bay.

Responsibilities:

- Coordinate with the Structure subsystem to ensure compatibility with the rocket airframe.

- Coordinate with the Recovery and Propulsion Subsystem in regards to cable management.

- Coordinate with the other avionics members in charge of the hardware.

- Update and create the documentation for your work.

- Attend and prepare slides for the weekly meetings.

Experience in the following is a plus:

- CAD

A general idea of the years unfolding:

- [S1-W4]: Start of the project

- [S1-W11]: Preliminary design review

- [S2-W8]: Critical design review

- [End of S2+Summer until EuRoC]: Testing and rocket integration

The Avionics subsystem is in charge of the design of the electronics and the software of the rocket. In this context, we are looking for a cable harness engineer to manage all cables going to and from the Avionics module.

Responsibilities:

- Design a cable harness solution for the Avionics subsystem.

- Interface with the Propulsion and Recovery subsystem to account for their needs.

- Coordinate with the other members also in charge of the Avionics hardware.

- Update and create the documentation for your work.

- Attend and prepare slides for the weekly meetings.

Experience in the following is a plus:

- CAD

- General Electrical knowledge

A general idea of the years unfolding:

- [S1-W4]: Start of the project

- [S1-W11]: Preliminary design review

- [S2-W8]: Critical design review

- [End of S2+Summer until EuRoC] Testing and rocket integration

Recovery

The purpose of the Recovery subsystem is to slow down the rocket’s fall to ensure a safe landing after its ascent.

This is usually done with parachutes, but experimentation is always welcome!

Available Roles:

The Recovery subsystem is in charge of getting the rocket back safely on the ground, usually with a set of two parachutes opened at different times (fast then slow) so that the rocket can touch down safely without drifting too far away. In this context, we are looking for someone to design, manufacture and test our new and improved set of parachutes!

Responsibilities:

- Design the parachute(s) needed to recover the rocket at the competition.

- Manufacture the designed parachutes.

- Design, plan and execute the testing of the parachutes.

- Coordinate with the other members of the Recovery subsystem.

- Update and create the documentation.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- Sewing Basics

- CAD

A general idea of the years unfolding:

- [S1-W3]: Start of the project.

- [S1-W9]: Preliminary Design Review.

- [S2-W3]: Critical Design Review.

- [S2-W8]: The system is supposed to be manufactured and ready for testing.

- [End of S2+Summer until EuRoC] Testing, Launch simulation+rocket integration.

The Recovery subsystem is in charge of getting the rocket back safely on the ground, usually with a set of two parachutes opened at different times (fast then slow) so that the rocket can touch down safely without drifting too far away. In this context, we are looking for someone to design, manufacture and test the second event mechanism, to deploy the second and main parachute.

Responsibilities:

- Update the design of the actual second event mechanism.

- Manufacture or plan the manufacture of the mechanism.

- Integrate the mechanism with the whole system, ensuring interfaces.

- Being part of the test campaign for the whole recovery subsystem.

- Update and create the documentation.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- General Stress Theory

- CAD

A general idea of the years unfolding:

- [S1-W3]: Start of the project.

- [S1-W9]: Preliminary Design Review.

- [S2-W3]: Critical Design Review.

- [S2-W8]: The system is supposed to be manufactured and ready for testing.

- [End of S2+Summer until EuRoC] Testing, Launch simulation+rocket integration.

The Recovery subsystem is in charge of getting the rocket back safely on the ground, usually with a set of two parachutes opened at different times (fast then slow) so that the rocket can touch down safely without drifting too far away. In this context, we are looking for someone to design, assemble and test the different lines linking parachutes and rocket parts together, alongside calculating the necessary swivel and other links between the line and the rigid rocket parts/parachutes.

Responsibilities:

- Design the different lines, the cords between the parachutes and the rocket, for the two parachutes.

- Avoid any issues with the tangle of the different cords of the parachutes.

- Do all the calculations needed to chose the right swivels.

- Being part of the testing phase of the parachutes and of the recovery system.

- Coordinate with the other member also charged of the parachutes and of the structure of the rocket.

- Update and create the documentation.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- Practical knowledge

- Sense of dynamical behavior

A general idea of the years unfolding:

- [S1-W3]: Start of the project.

- [S1-W9]: Preliminary Design Review.

- [S2-W3]: Critical Design Review.

- [S2-W8]: The system is supposed to be manufactured and ready for testing.

- [End of S2+Summer until EuRoC] Testing, Launch simulation+rocket integration.

Structures

The Structure Subsystem is in charge of designing and producing the rocket’s fuselage, as well as ensuring that it is capable of surviving mechanical and thermal stresses before, during, and after the flight.

Available Roles:

The Structures subsystem is in charge of the design, simulation and manufacture of all structural elements within the rocket. In particular, the Structures subsystem is in charge of designing, simulating and manufacturing the tanks for the engine. For this purpose, we are looking for an Engineer in charge of the Engine Tanks.

Responsibilities:

- Design the rocket’s tank and end caps.

- Work with propulsion to assure compatibility with their engine.

- Assure the tank’s structural role if a structural tank is chosen.

- Update and create the documentation.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- General mechanical engineering knowledge

- Aluminium welding techniques

- Structural and Thermal simulations

- CAD

A general idea of the years unfolding:

- [S1-W4]: Brainstorming start

- [S1-W6]: Design start

- [S1-W11]: Primary design review

- [S2-W1]: Manufacturing start

- [S2-W8]: Critical design review

- [End of S2+Summer until EuRoC]: Manufacturing and testing

The Structures subsystem is in charge of the design, simulation and manufacture of all structural elements within the rocket. In particular, the Structures subsystem is in charge of designing, simulating and manufacturing the Payload Integration Structure, which will all the team to integrate the Payload securely within the rocket. For this purpose, we are looking for an Engineer in charge of the Payload Integration Structure.

Responsibilities:

- Designing the system while taking into accounts the requirements.

- Assuring the structural Integrity of the payload with calculations and simulations.

- Follow the manufacturing process.

- Test the integration of the payload.

- Keep up to date the documentation of the system on the ERT wiki.

- Attend and prepare slides for the weekly meetings.

- Prepare slides for the preliminary and critical design review.

Experience in the following is a plus:

- General mechanical engineering knowledge

- Structural and Thermal simulations

- CAD

A general idea of the years unfolding:

- [S1-W4]: Brainstorming start.

- [S1-W11]: Preliminary design review.

- [S2-W8]: Critical design review.

- [End of S2+Summer until EuRoC]: Manufacturing and testing.

The Structures subsystem is in charge of the design, simulation and manufacture of all structural elements within the rocket. In particular, the Structures subsystem is in charge of designing the internal structural elements as well as the plate that will take the shock of parachute deployment. For this purpose, we are looking for an Engineer in charge of the Internal Coupler and Parachute Shock Plate.

Responsibilities:

- Designing the system while taking into accounts the requirements.

- Assuring with calculations and simulations the viability of the system.

- Consider the interfaces with other subsystems.

- Follow the manufacturing process.

- Keep up to date the documentation of the system on the ERT wiki.

- Attend and prepare slides for the weekly meetings.

- Prepare slides for the preliminary and critical design review.

Experience in the following is a plus:

- General mechanical engineering knowledge

- Structural simulations

- CAD

A general idea of the years unfolding:

- [S1-W4]: Brainstorming start

- [S1-W11]: Preliminary design review

- [S2-W8]: Critical design review

- [End of S2+Summer until EuRoC]: Manufacturing and testing

The Structures subsystem is in charge of the design, simulation and manufacture of all structural elements within the rocket. In particular, the Structures subsystem is in charge of designing and manufacturing the fins and integrate them on a fincan for the rocket. For this purpose, we are looking for an Engineer in charge of the Fincan.

Responsibilities:

- Design the rocket’s boattail and fincan coupler.

- Manufacture the boattail and overall fincan.

- Work with structure’s composite team.

- Assure the aerodynamics target of the rocket.

- Update and create the documentation on your work.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- General mechanical engineering knowledge

- Structural and CFD simulations

- CAD

A general idea of the years unfolding:

- [S1-W4]: Brainstorming start.

- [S1-W11]: Preliminary design review.

- [S2-W8]: Critical design review.

- [End of S2+Summer until EuRoC]: Manufacturing and testing.

The Structures subsystem is in charge of the design, simulation and manufacture of all structural elements within the rocket. In particular, the Structures subsystem is in charge of integrating the new engine provided by the propulsion subsystem inside the airframe. For this purpose, we are looking for an Engineer in charge of the Engine Integration.

Responsibilities:

- Design the rocket’s engine integration structure and interface parts.

- Manufacture the EIS and interface parts.

- Work with structure’s fincan team and with the propulsion team.

- Assure the engine’s thrust transmission to the airframe.

- Assure the accessibility of the plumbing by the propulsion team during assembly.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- General mechanical engineering knowledge

- Structural simulations

- CAD

A general idea of the years unfolding:

- [S1-W4]: Brainstorming start

- [S1-W6]: Design start

- [S1-W11]: Primary design review

- [S2-W1]: Manufacturing start

- [S2-W8]: Critical design review

- [End of S2+Summer until EuRoC]: Manufacturing and testing

The Structures subsystem is in charge of the design, simulation and manufacture of all structural elements within the rocket. In particular, the Structures subsystem is in charge of designing and simulating the airframe, fins and nosecone using composite materials. For this purpose, we are looking for an Engineer in charge of composites.

Responsibilities:

- Design the rocket’s fins, fuselage and nosecone using composite materials.

- Simulate the composite’s behaviour under thermal and structural loads.

- Design and follow the part’s manufacturing.

- Assure radio transparency for radio communication on the part of the fuselage reserved for the Avionics module.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- General mechanical engineering knowledge

- Experience with composite materials

- Structural simulations using composites

- CAD

A general idea of the years unfolding:

- [S1-W4]: Brainstorming start

- [S1-W6]: Design start

- [S1-W11]: Primary design review

- [S2-W1]: Manufacturing start

- [S2-W8]: Critical design review

- [End of S2+Summer until EuRoC]: Manufacturing and testing

The Structures subsystem is in charge of the design, simulation and manufacture of all structural elements within the rocket. In particular, the Structures subsystem is in charge of designing, simulating and manufacturing the Separation Mechanism. This mechanism allows the rocket to separate on demand to let the first parachute out.

Responsibilities:

- Update and upgrade the separation mechanism that has been developed over the past few years.

- Coordinate the design with the Recovery team to ensure interfaces.

- Plan and carry over the manufacture of the system.

- Testing of the mechanism under nominal and off-nominal scenarios.

- Update and create the documentation.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- General mechanical theory

- CAD

A general idea of the years unfolding:

- [S1-W3]: Start of the project.

- [S1-W9]: Preliminary Design Review.

- [S2-W3]: Critical Design Review.

- [S2-W8]: The system is supposed to be manufactured and ready for testing.

- [End of S2+Summer until EuRoC] Testing, Launch simulation+rocket integration.

Propulsion

The Propulsion subsystem is where the magic happens. Fire comes out on one end, pushing the rocket towards its objective.

This year, the team is aiming to fly its very first Liquid engine with Ethanol as fuel and Nitrous Oxide as the oxidizer.

Available Roles:

The propulsion subsystem is responsible for developing and integrating a 1kN bi-liquid rocket engine (Demo-A2) for the competition rocket, based on previous work done by the Hyperion project.

The engine design engineer will be responsible for the adaptation of the existing test engine Demo-A1 into a flyable version. The 2 main challenges are the ability of the Demo-A2 engine to sustain longer burn time (between 5 and 15 seconds, TBD) and the reduction of mass. As the internal design is already done, the focus will be put on external geometry, mainly using mechanical and more importantly thermal simulations.

The engine should be as simple as possible (a.k.a no regenerative cooling). Possible solutions are (but not restricted to): ablative chamber/nozzle, ablative internal insulation, film cooling, …

Responsibilities:

- Mechanical design and simulations of the engine.

- Thermal simulations of the engine.

- Pressure testing of the engine.

- Cold Flow testing of the engine.

- Hotfire testing of the engine.

- Update and create the documentation for your work.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- Thermal and mechanical simulations

- CAD

A general idea of the years unfolding:

- [S1-W1-8] Problem analysis, solutions catalog.

- [S1-W8-14] Solution choice and design for manufacturing.

- [S2-W1-6] Manufacturing, test.

- [S2-W4-EuRoC] Hotfire test, optimisation.

The propulsion subsystem is responsible for developing and integrating a 1kN bi-liquid rocket engine (Demo-A2) for the competition rocket, based on previous work done by the Hyperion project.

The plumbing integration engineer is responsible for the design and integration of the internal plumbing of the competition rocket rocket needed to operate a bi-liquid engine. The plumbing system shall be able to fill, purge, vent and pressurize the tanks, and to transfer propellant from the tanks to the combustion chamber

Responsibilities:

- Valve selection for the engine.

- Plumbing design that can be integrated in the restricted volume of the rocket.

- Manufacture and integration of the plumbing and the valves in the rocket.

- Testing of the subassemblies and of the final assembly.

- Update and create the documentation for your work.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- CAD

- High-pressure plumbing knowledge

- Good spatial representation

A general idea of the years unfolding:

- [S1-W1-10]: Valve selection, plumbing concept.

- [S1-W1-14]: Components order, tests.

- [S2-W1-6]: Rocket integration, tests.

- [S2-W6-EuRoC]: Hotfire tests, optimisation.

Payload

The Payload is the sub-system in charge of imagining, developing and integrating the scientific experiment powered by the rocket.

This years experiment is not yet chosen, give us your ideas!

Available Roles:

Coming…

Ground Segment

The Ground Segment subsystem is in charge of all ground operations before, during and after the launch.

This includes, among others, the management of a Ground Station equipped with radios and antennas, as well as a 9m tall Launch Rail.

Available Roles:

No roles for this year!

Flight Dynamics

The Flight Dynamics subsystem is in charge of all simulations related to the rocket in general.

It is in particular flight simulations with commercial tools as well as with home-made simulators, and fluidic studies on the aerodynamics of the rocket.

Simulations performed are, amongst others, predictions for the rockets trajectory, statistical drop-zones for nominal and off-nominal trajectories, aerodynamics/thermal/fluid analysis on the airflow around the rocket at various velocities.

Available Roles:

The Flight Dynamics subsystem is in charge of the rocket’s aerodynamic and flight performances. In this context, we are looking for a supersonic wind tunnel engineer.

The person filling this role will work on the design of a small scale supersonic wind tunnel. Considering the rareness of such infrastructure in Switzerland and in Europe, the association decided to build one in-house. A first feasibility study was realized during the Spring semester 2022. However, further improvements should be realized before beginning the manufacturing phase. Wind tunnels are used to simulate aerodynamic effects that would affect an object. To do so, a flow of gas is accelerated from a rest state to a velocity simulating the one the object will experiment during its movement. Such a tunnel could give invaluable results for the development of future rockets.

Responsibilities:

- Progress on the design and development of the Supersonic Windtunnel.

- Update and create the documentation for your work.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- Fluid Mechanics (in particular compressible flows)

- Physics (Optics, in particular Schlieren imaging)

A general idea of the years unfolding:

- [S1-W3]: Reading what has been done in previous projects.

- [S1-W14]: Second iteration of the design.

- [S2]: Improvement of the design.

The Flight Dynamics subsystem is in charge of the rocket’s aerodynamic and flight performances. In this context, we are looking for a flight simulator engineer.

The person filling this role will work on the in-house flight simulator developed by the EPFL Rocket Team. The results of these simulations are essential to validate our design and ensure proper flight characteristics. At the moment, external simulators are used. However, they all have their pros and cons and, although useful, they do not provide as much freedom in their use as a simulator developed internally. For this reason, the association decided to develop its own flight simulator. A certain basis is existent but further development is still needed for the simulator to perform efficiently. We hope to use it as principal support for the simulations at the 2023 competition.

Responsibilities:

- Progress on the design and development of the teams Flight Simulator.

- Update and create the documentation for your work.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- Programming (ideally Matlab)

- Data analysis and interpretation

- Physics

A general idea of the years unfolding:

- [S1]: Further develop the current in-house simulator.

- [S2]: Validate its results with experimental Data and cross-check with other external flight simulators.

The Flight Dynamics subsystem is in charge of the rocket’s aerodynamic and flight performances. In this context, we are looking for a flight simulations engineer.

The person filling this role will work on simulating the flight of the rocket under various scenarios as well as perform sensitivity analyses for the rocket taking part in the 2023 competition. This person will mainly use flight simulators but should be able to analyze and interpret the results. These simulations are crucial and used to determine and validate the design of the rocket. This person will, then, be a contact for other subsystems (Propulsion, Structure, …) should they have precise questions on the impact of different requirements.

Responsibilities:

- Perform the required flight simulations.

- Update and create the documentation for your work.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- Programming (ideally Matlab)

- Data analysis and interpretation

- Good interpersonal skills

A general idea of the years unfolding:

- [S1]: Determination of the general requirements for the rocket, sensitivity analyses.

- [S2]: Simulations to support the adopted design, adapt simulations to changes in design.

The Flight Dynamics subsystem is in charge of the rocket’s aerodynamic and flight performances. In this context, we are looking for an aerodynamic simulations engineer.

The person filling this role will work on Computational Fluid Dynamics (CFD) simulations for the rocket taking part in the 2023 competition. The results of such simulations are essential for the team as they guarantee that the rocket’s different components exposed to the external airflow produce as little drag as possible, or in other words, to ensure that the rocket is as aerodynamic as possible for the speed regime it will be flying. This person will also act as a consultant for other subsystems, whenever the aerodynamic performance of a certain airframe component needs to be determined and/or improved. Indeed, launch windows are limited in Switzerland. As a result, it is critical to ensure that the result of the simulations are as physically accurate as possible to be able to make the most of the authorized launches.

Responsibilities:

- Perform the required simulations when inquired by other subsystems.

- Update and create the documentation for your work.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- Fluid mechanics (in particular aerodynamics)

- CFD simulations (ideally ANSYS Fluent)

- Good interpersonal skills

A general idea of the years unfolding:

- [S1]: Determination of the shape of aerostructure components.

- [S2]: Simulations to support the adopted design.

The Flight Dynamics subsystem is in charge of the rocket’s aerodynamic and flight performances. In this context, we are looking for an aerodynamics engineer.

The person taking this role will work on the development of active aerodynamics (or mechanisms providing some degrees of active control) for this year’s rocket. In the competition, more points are awarded to rockets being capable to reach their altitude’s category as accurately as possible. For this reason, active control of the rocket would be game changing and represent a significant step forward for the team.

Responsibilities:

- Design a mechanism to achieve a set of requirements.

- Design a manufacturing method for such a mechanism.

- Manufacture the mechanism.

- Test and integrate the mechanism within a launch vehicle.

- Update and create the documentation for your work.

- Attend meetings and prepare summaries of work done and ahead.

Experience in the following is a plus:

- Fluid mechanics (in particular aerodynamics)

- CFD simulations (ideally ANSYS Fluent)

- Mechanical design

- CAD

A general idea of the years unfolding:

- [S1]: Feasibility study, quantify advantages provided by proposed elements.

- [S2]: Eventually manufacture and implement elements of interest.

RESEARCH PROJECTS

ICARUS

This year, Icarus project includes a team, made up of a few students entirely dedicated to the development and research around Guidance, Navigation and Control (GNC) algorithms as well as the real-time simulator to evaluate these algorithms.

This year, the team is mainly led by the automation laboratory (EPFL) with the 3 associated semester projects. If you are motivated but do not wish to work on a credited project, do not hesitate to send us an email at icarus@epflrocketteam.ch

PROJECTS AVAILABLE

- Robust touchdown control for a thrust-vector-controlled rocket

- Descent planning for a thrust-vector-controlled rocket

- Online controller adaptation for a thrust-vector-controlled rocket

This year, ICARUS project is developing its very first Hopper-type rocket allowing to maintain stability by directing the thrust of the engine and aiming at propulsively landing vertically. For this, a gimbal module allowing to redirect the thrust by two degrees of freedom has been designed. The objective is now to refine the design and to manufacture it before testing it. Ideally, a small team of 2 students with practical knowledge in mechanics and electronics would be perfect to work on this module. It is also possible to work on it as a credited semester project.

ROLES AVAILABLE

Role: Hopper Team _ Gimbal

Description: As a member of the team, you will be involved in the manufacturing, testing, and iteration of the design.

Profile/Skills: CAD (Solidworks), Previous experience in coding and hands-on projects preferred.

This year, ICARUS project is developing its very first Hopper-type rocket allowing to maintain stability by directing the thrust of the engine and aiming at propulsively landing vertically. Therefore, a landing leg module has been designed to guarantee the stability on the ground and to absorb the impact energy. The objective is now to manufacture a small-scale prototype and to test it in order to refine the final design. Ideally, a small team of 2 students with practical knowledge in mechanics and electronics would be perfect to work on this module.

It is also possible to work on it as a credited semester project.

ROLES AVAILABLE

Role: Hopper Team _ Legs

Description: As a member of the team, you will be involved in the manufacturing, testing, and iteration of the design.

Profile/Skills: CAD (Solidworks), FEM Simulation (Ansys), Previous experience in coding and hands-on projects preferred.

This year, ICARUS project is developing its very first Hopper-type rocket allowing to maintain stability by directing the thrust of the engine and aiming at propulsively landing vertically. A gimbal module and a landing leg module have been designed for this purpose. The objective is now to refine the design of the main structure and the electronics integration, to then manufacture it before testing it. Ideally, a small team of 2 – 4 students with practical knowledge in mechanics and electronics would be perfect to work in this team. It is also possible to work on it as part of a credited semester project to develop a roll control mechanism.

ROLES AVAILABLE

Role: Hopper Team

Description: As a member of the team, you will be involved in the manufacturing, testing, and iteration of the design.

Profile/Skills: CAD (Solidworks), Previous experience in coding and hands-on projects preferred.

HYPERION

This section of the Hyperion project deals with the design and construction of an engine using liquid oxygen (LOx) as oxidizer and ethanol as fuel. This class of engine will progressively integrate several technologies that will be used for the space-shot, such as regenerative cooling and electric pumps.

The first class B engine will be used on a test bench, and is intended to be manufactured in majority by the team.

ROLES AVAILABLE

Role: Responsible for the design of the motor (2)

Description: Sizing and design of the mechanical elements of the engine,

combustion chamber, nozzle and injector. The design will be adapted for additive

manufacturing.

Profile/Skills: MT-RO, GM, general knowledge of fluid management and

commercial components

Role: SLM Specialist (Spring 2023) (1)

Description: Responsible for engine manufacturing, study of Selective Laser

Melting manufacturing constraints, with the possibility of going to a shop to

manufacture parts.

Profile/Skills: MT-RO, GM, knowledge of metal additive manufacturing and general

mechanics

Role: Impeller/Volute Specialist (2)

Description: Responsible for the design of the fluidic part of the electric pumps of

the class B motor, based on the various works done so far.

Profile/Skills: MT-RO, GM, general knowledge of fluid mechanics and commercial

components, good experience in CFD and CAD

Profile/Skills: MT-RO, GM, general mechanical and CAD knowledge

Role: Seal Manager (1)

Description: Responsible for the dynamic sealing assembly of the electric pump

of the class B motor, using labyrinth seals around the shaft.

Profile/Skills: MT-RO, GM, MX knowledge in general mechanics, fluid mechanics

and CAD

Role: Responsible for the control of the pump electronics (1)

Description: Selection of electronic components, electric motor and power part of

electric pumps.

Profile/Skills: EL, MT-RO, electronic knowledge

Role: Responsible for cryogenic valves (1)

Description: Adaptation and qualification of a general purpose commercial valve

for use with cryogenic liquid oxygen.

Profile/Skills: GM, MT-RO, knowledge in fluid mechanics, general mechanics and

CAD

One of the most critical aspects in the development of a bi-liquid rocket engine is the test area. It must be robust, secure, and highly functional to ensure the safety of users even in the event of a major problem with the engine.

ROLES AVAILABLE

Role: Test Bench Engineer (3)

Description: Development of a vertical test bench for a bi-liquid engine. The goal is to design and manufacture a solid test bench that meets precise specifications.

Profile/Skills: MT, GM, general engineering knowledge in structural mechanics and/or manufacturing

Role: Sensors and information acquisition Engineer (2)

Description: Determine which sensors (Thrust, pressure and force) would be optimal, then integrate it to the test bench. Calibrate the sensors from a technical sheet. Manage the data acquisition system to export the test’s data

Profile/Skills: MT, EL, general engineering knowledge and mesuring techniques.

Role: Valves and piping Engineer (1)

Description: Responsible for the integration of the plumbing and the valves onto the test bench.

Profile/Skills: MT, GM, general engineering knowledge in structural mecanics and/or manufacture and/or fluid mecanics.

Role: Test bench electronics Engineer (1)

Description: Develop the electronics and wiring of the test bench. A video acquisition system will also be developed, mainly built from commercial products.

Profile/Skills: MT, EL, General engineering knowledge in electronics or video systems.

Role: Test facility team member

Description: As a team member, you offer help to the other team members on manufacture and design.

FORMATION PROJECT

SPACE RACE

This project involves building a relatively simple rocket in teams of 5-7 students. This project allows to learn the basics of rocketry while learning to work in a team. It is mostly aimed to the first and possibly second year students of EPFL.

All sections are welcome.

START YOUR SPACE CARRIER - COMPETITION

Gain experience and credibility

through credited projects and industry training, while gaining internship opportunities and referrals.

Meet your future employer

at one of our events where you will have the opportunity to talk with sponsors and partners in the space industry.

Expand your network

by meeting employees and contractors active in the space industry as well as talented students from our projects.

LEARN IN A SAFE SPACE - SPACE RACE

Take advantage of ERT’s

unique infrastructure: a large and secure workshop, dedicated mentors and state-of-the-art technology to ensure the best possible learning experience.

Meet your mentor

who will help your team throughout the year to enhance your learning experience and ensure that your rocket is well built, safe and will fly successfully.

Earn certifications

related to rocket machining, manufacturing or design: you will benefit from several workshops and launches to obtain them throughout your year of learning.

No pressure during the year.

You will have a little competition just for fun, and you are here to learn. But you are welcome to join the competition team after your training year.

BECOME A PIONEER - RESEARCH DIVISION

Create your innovations

and participate in crazy challenges, like our Icarus project: be the first student team to land its rocket like SpaceX.

Unleash your potential

by getting space to test all your cool, crazy and experimental ideas on one of our rocket related projects.

Not sure if you want to participate in a project for an entire academic year? Consider choosing one of our credited semester projects! Each year, we offer many projects, in all fields, already followed by EPFL professors. Find yours!